Overview to Putting Up An Earth Anchor for a Stronger Foundation

Wiki Article

High-Performance Support Equipments for Any Kind Of Application

High-performance anchor systems are crucial in ensuring safety and security and security across a multitude of applications, from building to aerospace. Their sophisticated design supplies functions such as enhanced load capability and resistance to environmental aspects, which are important for keeping architectural stability. The choice and implementation of these systems can be complicated, affected by various industry-specific demands. Understanding the subtleties of different anchor types and their particular installation methods is important. What considerations must be taken into consideration to optimize their effectiveness and long life in tough atmospheres?Kinds of Support Systems

When thinking about the diverse applications of support systems, what are the main kinds that professionals rely on for high-performance outcomes? Support systems can be broadly classified into a number of kinds, each made to fulfill specific demands based upon the nature of the tons and environmental problems.

The very first classification is mechanical supports, that include expansion anchors, wedge anchors, and screw anchors. These are typically utilized in concrete and masonry applications, giving robust holding power with mechanical interlock or rubbing.

An additional considerable kind is sticky supports, which use chemical bonding agents to secure the anchor within the substratum. This type is particularly beneficial in applications where high tensile toughness and resistance to shear pressures are essential.

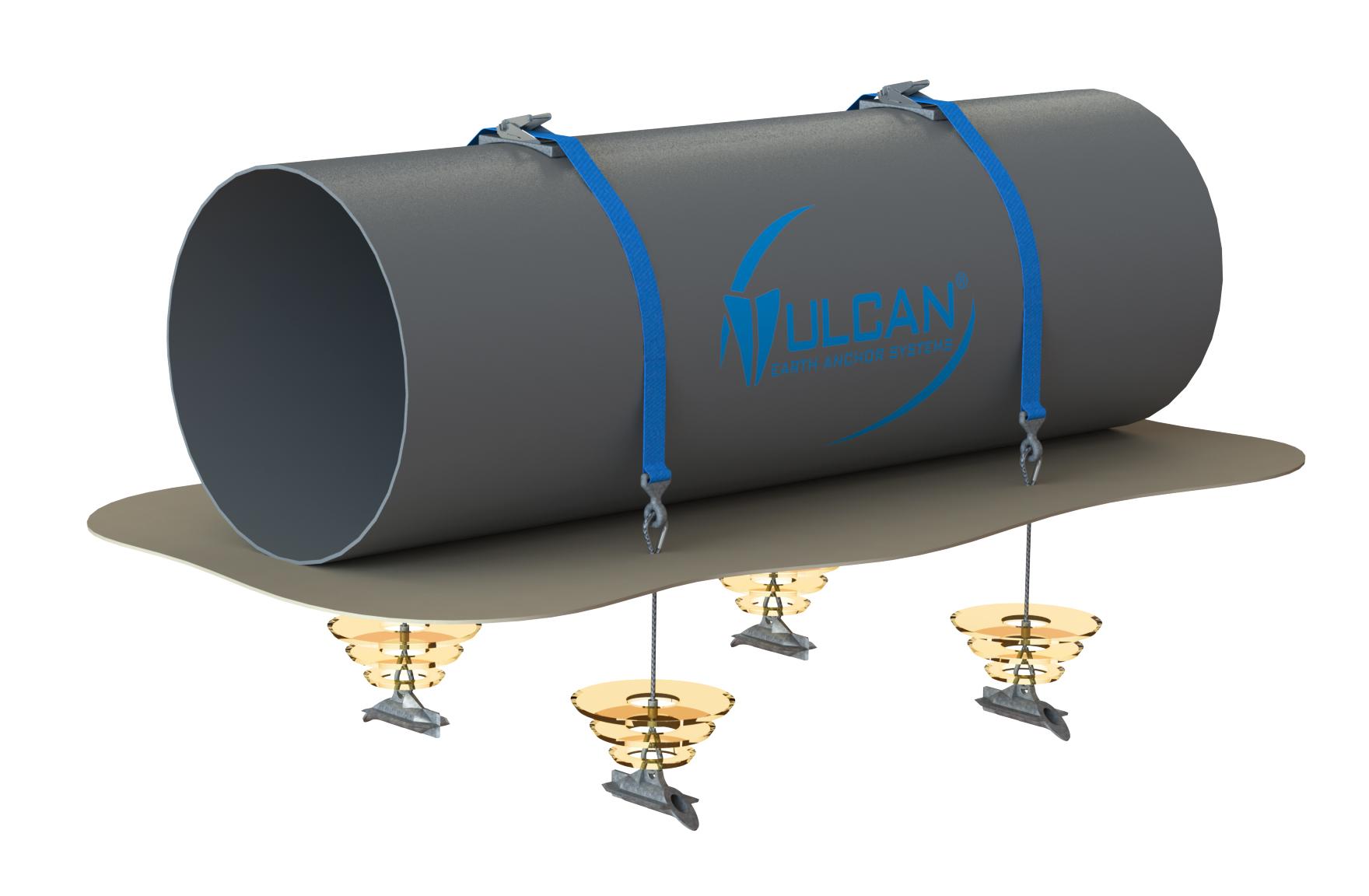

Furthermore, there are passive supports, such as deadman anchors, which depend on the weight and resistance of surrounding products to secure things. They are typically utilized in outside applications or where dynamic loads exist.

Last but not least, there are customized anchor systems like ground supports, which are made use of in civil engineering and building tasks for stabilizing structures. Each kind of support system is made with certain efficiency metrics in mind, making sure optimal safety and security and performance throughout various applications.

Key Features and Benefits

High-performance support systems supply a series of essential functions and benefits that boost their performance in numerous applications. Among the main attributes is their premium load capacity, which ensures security and security under significant tension conditions. This is achieved with innovative products and design layouts, enabling reliable efficiency sought after environments.Additionally, these systems typically integrate ingenious innovation such as deterioration resistance and flexibility to different substrates. This not just extends their lifespan yet also lowers upkeep expenses, making them a cost-efficient remedy in time. The versatility of high-performance anchor systems enables seamless assimilation right into numerous structures, improving their use across many projects.

Another notable advantage is simplicity of installation. Numerous high-performance anchors are made for straightforward and fast release, decreasing labor time and increasing total job efficiency. Additionally, their light-weight nature helps with transportation and handling, adding to structured operations.

Applications in Various Industries

In the transport market, high-performance supports are used to Website secure roadway my site and rail infrastructure, contributing to the safety and security of passengers and automobiles. Their reliability is vital in preventing structural failings that can result in disastrous accidents. Additionally, in the renewable resource sector, these supports are critical for securing wind turbines and photovoltaic panel installations, ensuring they stand up to ecological stress and anxieties while making best use of efficiency.

The aerospace market additionally makes use of advanced anchoring services to protect parts throughout production and transport, where accuracy and integrity are important. In each of these applications, the choice of proper support systems can significantly impact overall project success, highlighting the flexibility and necessity of high-performance anchors across various industrial landscapes.

Setup Techniques and Tips

Proper installment of high-performance support systems is vital to their effectiveness and longevity. To guarantee ideal performance, it is necessary to comply with established installation techniques customized to the details kind of anchor system and application.Begin by extensively analyzing the installment site, consisting of the substratum problems, load needs, and ecological aspects. Exact dimensions straight from the source and positioning are crucial; make use of laser levels or plumb lines to maintain precision. When exploration, pick the ideal little bit dimension and kind for the support system, ensuring accurate and tidy holes to prevent material damage.

Utilize the recommended torque settings during securing to avoid over-tightening or under-tightening, which can compromise the support's stability. Additionally, stick to the supplier's guidelines concerning spacing and edge ranges to optimize lots distribution and minimize potential failure points.

Always use personal safety equipment (PPE) throughout the installment process, and take into consideration utilizing specialized tools made for high-performance supports to enhance performance and safety and security. Carry out a comprehensive assessment post-installation to confirm that all parts are firmly secured and in placement, making certain the anchor system is ready to perform under expected tons.

Upkeep and Safety Considerations

To make certain the long life and integrity of support systems, normal upkeep and safety and security considerations need to be prioritized. Regular inspections are important to identify wear and tear, deterioration, or any type of structural shortages that might endanger the anchor's efficiency. A comprehensive upkeep routine need to include examining the stability of support components, such as plates, bolts, and welds, and making certain that all connections are secure.In addition, environmental elements can considerably affect support systems. Direct exposure to rough weather problems or corrosive materials can speed up wear and tear. Using safety finishings or making use of corrosion-resistant products can boost resilience and extend service life.

Security considerations are extremely important; individuals must stick to manufacturer guidelines regarding tons restrictions and functional procedures. Educating workers on appropriate use and possible threats is critical in stopping accidents. Implementing a safety monitoring system that consists of routine drills and responses mechanisms can grow a society of safety and security.

Final Thought

In conclusion, high-performance anchor systems represent a vital innovation across several industries, providing exceptional tons ability, corrosion resistance, and adaptability. Routine upkeep and detailed evaluations additionally enhance their efficiency, developing these support systems as necessary components in securing frameworks and equipment.High-performance anchor systems are crucial in ensuring safety and security throughout a plethora of applications, from building to aerospace.High-performance anchor systems provide a range of essential functions and advantages that enhance their efficiency in different applications. The convenience of high-performance anchor systems enables for smooth combination into various frameworks, boosting their functionality throughout numerous jobs.

In diverse markets, high-performance anchor systems play an essential role in making sure architectural honesty and safety (Earth Anchor).In final thought, high-performance anchor systems stand for an important advancement across multiple industries, supplying extraordinary tons capacity, deterioration resistance, and convenience

Report this wiki page